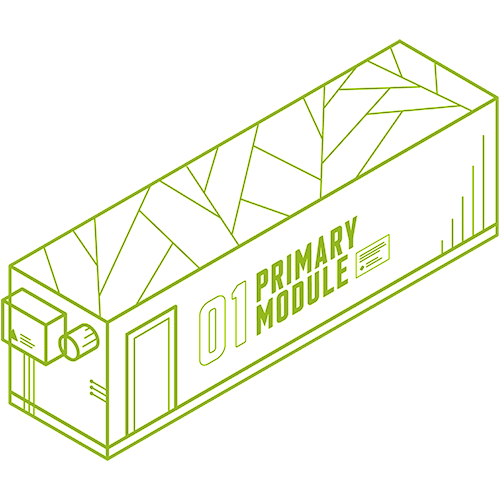

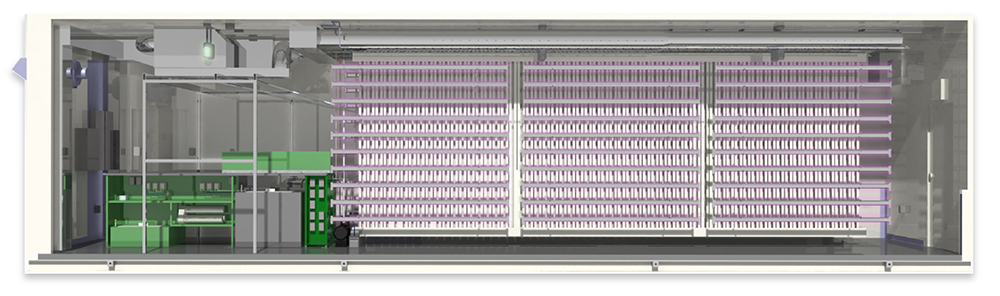

PRIMARY MODULE

THE FOUNDATION OF THE MODULAR FARM SYSTEM.

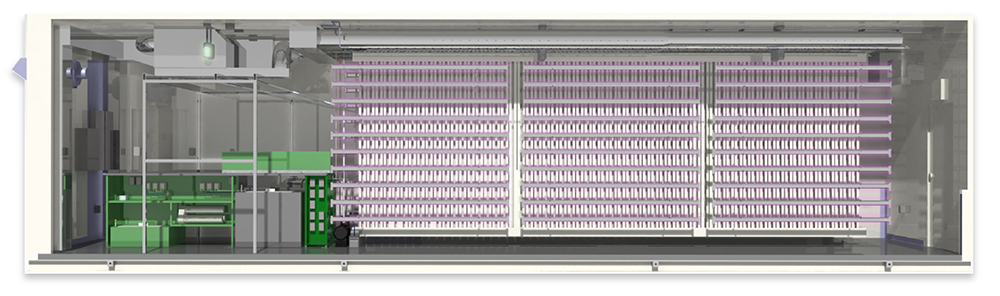

PRIMARY MODULE

THE FOUNDATION OF THE MODULAR FARM SYSTEM.

PLANT VOLUME

Installed are 3840 plant sites within 240 x 2.44m Zip- Grow Towers however there is the flexibility to adjust the placement for small or large plant types.

LIGHTING

The LED lights, which were specifically designed to grow crops and to promote maximum growth, are placed at optimal distance to the plant canopy.

INSULATION

With an 4.0+R value at 100mm thick, and coupled with a sealed controlled environment, the insulation is improved by approx 60% compared to a shipping container. External climate influences are also less impactful.

AIR

Custom HVAC design and dehumidifiers are capable of removing and recapturing over 190 litres of transpired or evaporated water from the air.

SIZE

The ‘purpose-built’ 3x3x12m farm has an increase of 0.25m in height and 0.5m in width compared to a standard shipping container therefore allowing wider aisles for easy planting, crop inspections and harvesting.

CLEAN

Chemical free, NO pesticide, NO insecticides and NO herbicides. Clean fresh produce.

WATER

Using less than 40lt of water a day; inside the farm we are capable of removing and recapturing up to 190 litres of transpired or evaporated water from the air via our dehumidification process.

THE PRIMARY MODULE

The Primary Module is the ultimate high-volume container farm. Engineered to support the highest quality of plant health and efficient growing, the Primary Module is capable of industry leading harvest yields. It also comes packed with an extensive list of automation tools, advanced climate controls, quality-of-life features and customization options that allow the farm to operate practically anywhere and anytime in the world. The Modular Farm is constructed from a 3x3x12m pre-fabricated composite steel container. It weighs approximately 8,000kgs and has an insulation value of R22-R35. The container interior can simulate different growing environments for a range of plant growing arrangements. Each system is equipped with stainless steel workspaces and enamel-coated and mould-resistant structures. There is no use of powder-coat inside our farms other than the subframe on the exterior, aluminium LED curtain rollers and circulation fan mounting brackets. All materials used are food-safe.

PLANT VOLUME

Installed are 3840 plant sites within 240 x 2.44m Zip- Grow Towers however there is the flexibility to adjust the placement for small or large plant types.

LIGHTING

The LED lights, which were specifically designed to grow crops and to promote maximum growth, are placed at optimal distance to the plant canopy. Installed in the Primary Module are 60 x 2.44m Intravision SpectraBlades.

INSULATION

With an 4.0+R value at 100mm thick, and coupled with a sealed controlled environment, the insulation is improved by approx 60% compared to a shipping container. External climate influences are also less impactful.

AIR

Custom HVAC design and dehumidifiers are capable of removing and recapturing over 190 litres of transpired or evaporated water from the air.

SIZE

The ‘purpose-built’ 3x3x12m farm has an increase of 0.25m in height and 0.5m in width compared to a standard shipping container therefore allowing wider aisles for easy planting, crop inspections and harvesting.

CLEAN

Chemical free, NO pesticide, NO insecticides and NO herbicides. Clean fresh produce.

WATER

Using less than 40lt of water a day; inside the farm we are capable of removing and recapturing up to 190 litres of transpired or evaporated water from the air via our dehumidification process.

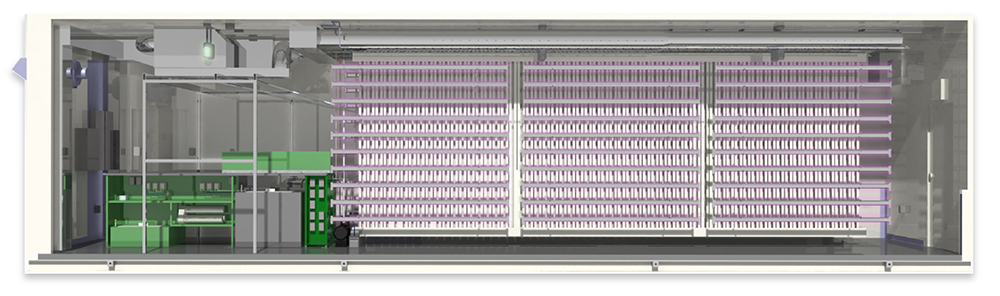

THE PRIMARY MODULE

Our Modular Farm System is a complete vertical farming suite designed from scratch to do one thing very well; consistently grow healthy food. We’ve redesigned and rebuilt everything we knew about container farms to bring the world our Primary Module. From the ‘purpose-built’ container, to the Intravision SpectraBlade LEDs, to the seedling table that took eight months and four prototypes to satisfy our co-founders; every detail was scrutinized to deliver an indoor farm unlike anything else on earth. Step inside a Modular Farm and you’ll never look at container farms the same again.

THE PRIMARY MODULE

Our Modular Farm System is a complete vertical farming suite designed from scratch to do one thing very well; consistently grow healthy food. We’ve redesigned and rebuilt everything we knew about container farms to bring the world our Primary Module. From the ‘purpose-built’ container, to the Intravision SpectraBlade LEDs, to the seedling table that took eight months and four prototypes to satisfy our co-founders; every detail was scrutinized to deliver an indoor farm unlike anything else on earth. Step inside a Modular Farm and you’ll never look at container farms the same again.

PLANT VOLUME

Installed are 3840 plant sites within 240 x 2.44m Zip- Grow Towers however there is the flexibility to adjust the placement for small or large plant types.

LIGHTING

The LED lights, which were specifically designed to grow crops and to promote maximum growth, are placed at optimal distance to the plant canopy.

INSULATION

With an 4.0+R value at 100mm thick, and coupled with a sealed controlled environment, the insulation is improved by approx 60% compared to a shipping container. External climate influences are also less impactful.

AIR

Custom HVAC design and dehumidifiers are capable of removing and recapturing over 190 litres of transpired or evaporated water from the air.

SIZE

The ‘purpose-built’ 3x3x12m farm has an increase of 0.25m in height and 0.5m in width compared to a standard shipping container therefore allowing wider aisles for easy planting, crop inspections and harvesting.

CLEAN

Chemical free, NO pesticide, NO insecticides and NO herbicides. Clean fresh produce.

WATER

Using less than 40lt of water a day; inside the farm we are capable of removing and recapturing up to 190 litres of transpired or evaporated water from the air via our dehumidification process.